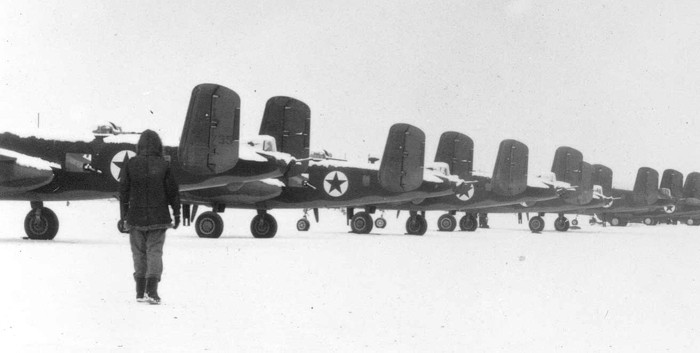

B-25D30, Alaska. Photo USAAF via Von Hardesty.

No one can better describe events than someone who was a witness and actual participant. In the process of gathering information concerning the combat employment of the B-25 in ADD [long-range aviation], one of the authors of Mir Aviatsii — V. M. Ratkin — had at his disposal the recollections of a participant in the receipt of and familiarization with these bombers, Guards Major General of Engineers A. M. Akvilyanov. This is the first publication of these recollections in English translated by James F. Gebhardt with kind permission of Mir Aviatsii.

The first four B-25s, which crews from NII [Scientific Research Institute] and Headquarters VVS had flown in from Basra, Iraq, were at Kratovo airfield [1]. Several men from these crews had been in the USA, where they had participated in a compressed period of study of the B-25 aircraft at its production facilities. Among them were pilot Lieutenant Colonel Romanov, navigator Lieutenant Colonel Molchanov, and flight engineer Captain Zebin, all of whom were assigned to commensurate positions in our division [2] for the purposes of assisting our flight crews and maintenance personnel in their transition to the B-25.

The 37th BAP (Bomber Aviation Regiment) of Siberians, which was the first regiment in the 222d BAD, had also just arrived and was stationed at this same airfield. The commander of this regiment was Lieutenant Colonel Katarzhin, the senior regiment engineer was Major of Technical Services Ya. P. Pristup, the deputy senior engineer was I. S. Petrov, the engineer for ESO (special electrical equipment) was Captain Beskorovannyy, and the engineer for armaments was Captain of Technical Services Poprushko. It should be noted that this regiment was a solid organization, a cohesive collective that carried out its military duty in an exceptional manner. It had later been designated the 13th Guards Red Banner Roslavl Regiment.

The ferry crews quickly familiarized us with the aircraft, its engines, equipment, and armaments. They warned us that the red handles, knobs, and levers were emergency control devices and we should better not touch them. They informed us that the on-board documentation from which we could familiarize ourselves with the aircraft was all present. They conducted demonstration flights and then departed. It was left to us quickly to master everything and commence combat operations with this aircraft.

We found that all the required descriptions, instructions, and schematics published by the manufacturer were in the on-board documentation, but in the English language, which we did not know. By all outward appearances, the documentation was exceptional. It was printed on thick glossy paper with colored schematics, sketches, drawings, and so on. The instructions for maintenance of the aircraft were particularly attractive. The text was accompanied by clear color cartoons, which were understandable without knowledge of the English language, and which instructively pointed out the consequences of mistakes and negligence of the pilots in the air and of mechanics on the ground. These visual aids, which often used humor as a tool, were always helpful and certainly deserved duplication in our own renditions of these instructions.

The caricatures were amusing but we had to master the basics. This was a difficult problem, the more so because the 125th BAP would arrive right behind the 37th BAP. Considering all the obstacles, the following method was chosen to master the aircraft. At our request, with the assistance of General Repin, the chief engineer of the VVS KA [Red Army Air Forces], a team of specialists of the New Equipment Bureau (BNT) of the Central Aero-hydrodynamics Institute (TsAGI), along with translators and engineers of the NII VVS KA who were particularly interested in new equipment, arrived at the division. Our maintenance personnel and mechanics from the repair base disassembled one B-25C down to major sub-assemblies in a hangar to permit familiarization with all systems and assemblies, and the best approach to all aggregates and assemblies of construction. A time schedule was developed jointly with the BNT team for the development and compilation, over the course of a month, of all necessary training materials—posters, system schematics, detailed sketches, instructions for flight and maintenance personnel, and so on—in the Russian language. In turn, the leadership of TsAGI and NII VVS tasked their specialists who were participating in these efforts to exploit everything that was new that could be of some interest for our own [Soviet] design bureaus [3]. We, in turn, requested that they produce materials for our training base.

In order to stimulate the work of the TsAGI team in our interests [222d BAD], we established the following understanding. If the TsAGI team adhered closely to the agreed upon schedule for development and duplication (in blueprints) of training devices, they would be fed in accordance with the no. 5 (aviator’s) rations norm [4]. If they did not meet the schedule, they would all be fed in accordance with the no. 2 rations norm. Viewed in hindsight, this may seem an amusing and, perhaps, despotic method. But in wartime conditions and our circumstances, associated with the time-sensitive preparation of the regiments for combat employment, this was an effective and necessary approach.

The problem of training was resolved, but the no less important matter of providing the regiments with the necessary ground support equipment remained. They had to have lifting devices, trestles and stands, devices to warm the engines, and so on. In addition, each aircraft had to be reconfigured before it was turned over to the regiment. As a matter of fact, in the USAAF a B-25 crew consisted of six men: two pilots, navigator, bombardier, radio operator/gunner, and gunner. Our crew consisted of five men, the functions of navigator and bombardier being assigned to our navigator. The navigator’s working space with his corresponding instrument panel was located in the compartment behind the pilots’ seats. Therefore we transferred all the navigator’s instruments to the nose compartment, where we also mounted our own collimator sight NKPB-7.

The fuel cells were not protected by fire-preventing neutral gases. We considered this to be unacceptable and therefore, with the assistance of the design bureau of NKAP (People’s Commissariat of Aviation Industry) Plant No. 156, a system was rapidly developed to vent spent engine exhaust gases into the fuel cells. At the same time we realized that auxiliary fuel cells holding up to 220 gallons could be installed in the aircraft under the wings and in the bomb bay.

Soviet aviation production facilities had their own enormous production schedules and difficulties. Therefore, in order to ensure that these modifications to the aircraft were accomplished in a timely manner, I personally appealed to the chief of the aviation department of the Central Committee of the Communist Party (TsK VKP(b)), who at that time was Major General of Aviation N. A. Shimanov. He listened very attentively to our requests and literally in my presence passed down by telephone his decisions regarding these issues. The design bureau engineers and team of workers of a plant that had remained in Moscow [5] very quickly developed and produced everything that was required for the reconfiguration of the aircraft. These same personnel, along with workers of the Monino repair base and VVS maintenance personnel carried out the reconfiguration of the regiments’ aircraft. The order was also issued for the development and production of auxiliary external (wing-mounted) and internal (bomb bay) fuel cells with the exhaust-gas protection feature installed.

Now a few words regarding the characteristics of the B-25. This was a twin-engine, by American standards medium bomber with tricycle landing gear. It had a maximum take-off weight of 32—34,000 pounds (16 tons). Its engines were Wright Cyclone R-2600-13/29 twin-row 18-cylinder radials with a maximum rating of 1600 h.p. They burned only 100-octane fuel, which until 1944 was delivered by sea from the USA in 5-gallon cans! Imagine what kind of difficulties were experienced by our support personnel during the refueling of this aircraft from cans, especially in winter conditions. This aircraft differed markedly from Soviet-produced aircraft in the proliferation and complexity of its electrical, radio, special equipment, and armaments. It had a vast array of communications and radio-navigational gear, electro-mechanical instruments, and automatic devices. The remote-controlled guns and bomb-release devices were totally electrically controlled. The aircraft was well armed with paired heavy (12.7mm) machine guns in mounts (Bendix Amplidyne turrets) that we encountered for the first time. They had servo-electrical motors with synchronized meters and electro-mechanical boosters. Among the radio and radio-navigational devices, I should point out the SCR-274 transmitter-receiver, SCR-269 Bendix radio compass, and Norden bombsight. The engines had a system for reducing viscosity of the oil with gasoline [necessary to simplify cold starts]. The nose gear had a shimmy damper and a number of other innovations (for us).

Despite the number of the B-25’s technical advances, the first incidences of freezing temperatures showed that this airplane was not equipped for utilization in Russian winter conditions. We experienced massive numbers of failures of individual components of the aircraft: electrical instruments, armaments, frozen and burst hydraulic brake lines, the controls for raising and lowering the landing gear, flaps, and bomb bay doors. Oil coolers cracked, engines misfired because of spark plug failures, cracks appeared in the leads to the plugs, and the carburetors failed.

We also had many problems with the rubber fuel and oil cells, which were made from several layers of rubber with varying physical characteristics. The manufacturer had calculated that if a projectile or shell fragment penetrated a fuel cell, the middle layer of raw rubber would swell upon contact with the gasoline or oil and seal up the hole. However, with the onset of sharply falling temperature of the surrounding air, which happened frequently in our part of the world, the inner layer of the fuel and oil cells began to crack, and under the influence of the gasoline (and oil) the rubber in the middle layer “gave way”. Pieces of dissolved (jelly-like) raw rubber found their way into the fuel (oil) cell and, more importantly, plugged the holes in fuel and oil lines and the fuel filters. The replacement of these fuel cells was quite complicated, time-consuming, and backbreaking work, particularly when there were no exchange cells, and if the work had to be accomplished in cold temperatures or when snow was falling. Because of the technical characteristics of these “Americans”, in the winter our maintenance personnel as a rule experienced frozen and wind-burned faces and swollen and cracked hands and fingers. The distinctive Russian savvy, resourcefulness, initiative, and great industriousness and forbearance of our engineering and maintenance personnel came to the rescue.

Despite all the difficulties and the shortages of adequate quantities of ground support equipment for the aircraft, the order to send the regiment off to combat duty with these new aircraft was carried out on time. The first to execute their combat missions were the crews of the 37th BAP, followed 2—3 weeks later by the remaining regiments. The entire division was flying combat sorties and at the same time intensively continued to upgrade their technical service of the aircraft. The air and ground crews polished their skills in flying the aircraft and working on it at any time of the day or night and during poor weather conditions. It should be stated that this improvement continued until the end of the war, due not only to better mastery of and employment of the aircraft in combat but also to the receipt of new and more modern versions of the aircraft: B-25C, B-25D, B-25J, and B-25G. We also continued to receive combat aircrew replacements.

Before the end of 1944, our corps [6] practically had a monopoly on the demand for B-25s, and therefore we were keenly aware of the tempo of their delivery via lend-lease. Spare parts, aggregates, hoses, tires, engines, and other materiel were delivered to us in quite limited quantities in 1942—43. New difficulties were added to those already listed. These included the premature failure in winter of the outer casings of the tires and disk brakes [7], the constant demand for auxiliary fuel cells, and local manufacture or supply of specific engine parts, specialized ground support equipment, spark plugs, and plug wires.

Guided by support of the Central Committee in the form of General Shimanov, and commensurate directorate of the VVS KA, we appealed directly to the management of NKAP plants. Despite their exceptional war production obligations, these manufacturing enterprises responded rapidly to our requests. Representatives from the serial design bureaus came to us and we showed them examples of what we needed. When we did not have examples, we drew up sketches of what was required. In short order we established and qualified the technical requirements for the manufacture of all these items. After an agreed upon time, followed by inspection of the developmental examples, we began to take delivery of fuel cells, rubber tires, cranes, and a series of spare parts for engines and aircraft. It must be said that our improvised production fully justified itself and when mounted on the aircraft these parts were more reliable than the American components they replaced. It must also be noted that technical agreements signed by us as users and the representatives of the production facilities, by which serial production of all these items was realized, were executed without unnecessary ratification “at the top”, as was required before the war.

In the same vein, later we learned that bureaucracy was also not in vogue in the USA. From documents that came with the aircraft we learned that the wartime commander in chief of the USAAF, General Hap Arnold, issued an order that empowered a certain Major Brown, I repeat—major (apparently a lead engineer), to make decisions regarding the B-25 and to pass them down in the form of requirements to the manufacturer—North American, which was a lead supplier (general contractor). This major also issued instructions to military units who were using the aircraft. We considered this procedure to be fully justified.

As we gained experience in the combat employment of the B-25 aircraft, we discovered specific deficiencies in the design and construction of several of its components. Our own engineers and mechanics came up with corrective suggestions. We discussed these among ourselves and periodically sent them off to the chief of the import commission of the VVS KA, General Levendovich. And wouldn’t you know, two or three months later we would receive B-25 aircraft in which our complaints and recommendations, as a rule, were addressed. This responsiveness of the manufacturer is explained by the energetic actions of the corresponding representatives of the Soviet Union in the USA and the significant authority given to the above-mentioned Major Brown. This system that functioned without official stamps and countless authorizing signatures also proved itself regarding foreign orders. The war could not wait for rank bureaucracy.

Our RGK (reserve of the supreme high command) division conducted intensive combat work with all three regiments day and night, primarily supporting Western Front [8]. Unexpectedly, at the end of 1942 they assigned us to the 1st Bomber Corps of the VVS, which at that time was commanded by Major General of Aviation V. A. Sudets [9]. His deputy for IAS (aviation engineering service) was Engineer Lieutenant Colonel A. P. Shepelev. Working conditions for the division were not improved by this change, the more so because some of the documents for the “top” we now were required to sign at the corps level. And we frequently were summoned to corps headquarters to give reports on how we were working.

The corps specialists, naturally, were not familiar in depth with our foreign equipment. The 1st BAK did not have its own technical repair units and they were unable to provide us with technical advice or assistance at the required level to repair our aviation equipment. Taking into consideration the capabilities of the corps chief engineer, and in the interests of the required rapid response, as before we turned to the services of the VVS KA, to industry, and when special problems arose, also to the Central Committee and Comrade Shimanov. Strange as it may seem, these circumstances became more frequent with our transfer to the 1st BAK. If the delivery of new B-25 aircraft from the USA was more or less normal, then the situation in spare parts, engines, aggregates, and equipment grew steadily worse. The Americans had put us on short rations; “choke points” were experienced for the first time because of a number of our “transgressions” in the employment of as yet insufficiently mastered equipment.

B-25D30, Alaska. Photo USAAF via Von Hardesty.

Now a few words regarding the ferrying of the B-25 from the USA. Early in the war, about to the end of 1942, B-25 aircraft were flown by American crews from the USA via the southern route across northern Africa, Syria, and Iran to an airfield at the port city of Basra, where they were received and ferried to our division [10]. But this route was long and its traverse of a number of other countries was in itself a cause of difficulty and delay. In response to requests by our representatives in the USA, the ferry route was shifted to the north. The Americans flew the aircraft to an airfield at Fairbanks, Alaska. Here, under the leadership of Hero of the Soviet Union I. P. Mazuruk, was based a group of Soviet ferry pilots [11]. These pilots flew the B-25s onward to the Krasnoyarsk airfield. Our division pilots received the aircraft at Krasnoyarsk and flew them to our division base. The multiple-stage northern route made great demands on Soviet maintenance personnel, especially in the winter, regarding receipt and inspection of the aircraft and all of its on-board equipment, instruments, emergency supplies, and so on. There were some instances when a portion of the emergency equipment (rubber rafts, rifles, down-filled sleeping bags, rations, and so on) was missing [12], and engineering-technical personnel of the division had to scurry about and locate them.

From all of this it is obvious that the serviceability of the aircraft pool and the combat readiness of the division’s units were entrusted to us, beginning with the ferrying itself and ending with the repair of the aircraft from combat damage in conditions of persistent shortages of parts and particularly of engines. At the same time, the command element of 1st BAK, aware of the division’s high level of combat readiness, employed it intensively. The division commander systematically assigned missions not only for bombing enemy strong points and airfields but also to “work over” the forward edge of the front line, and in daylight, no less. Because it was not a dive bomber, the B-25 was somewhat lethargic at low altitudes and the regiment began to experience significant losses, which were not being replaced by new aircraft. In a short time the number of combat ready aircraft available fell sharply.

We were faced with a difficult problem. Either we would soon become “horseless” and after such gigantic effort to master this foreign equipment they would send us to the rear for reconstitution on other airplanes [13], or we had to find another method of employment. Division commander Titov called together the division’s command personnel to discuss this problem. By this time, during the ferrying of the aircraft on the long sections of the route, using American flight computers we had begun to figure out the most efficient flight regimes for flight range and duration [14]. Analyzing these ferry flights, we came to the conclusion that if we mounted auxiliary fuel cells in the B-25, it could and should be employed as a long-range bomber. From this we decided that our real role was in long-range aviation (ADD). Our opinion was backed up by the experience of the combat work of ADD units that flew the Il-4 [15], which were based along side us at Monino airfield. All the time we had been looking at their flights and comparing them with our own. Considering and analyzing all of this information, the commanders’ conference made the following decision: without advertising or reporting it to the staff of 1st BAK, conduct an experimental flight into the rear of the country to a specific range in a combat profile, with a bomb drop at the turnaround point of the route. Division commander F. V. Titov took upon himself the responsibility to clear the flight with PVO strany [national air defense] and we, the headquarters specialists of engineering, navigation, and flight services, took care of preparing the crew and aircraft for this experiment.

A flight route was selected to the target some 1500 kilometers distant with a bomb load of 2000 kilograms. The aircraft was outfitted with a locally produced 220-gallon fuel cell in the bomb bay. This “covert” flight was flown at an altitude of from 3000 to 4000 meters with an average cruise speed of 300—330 km/hr to the bombing range. The results of this experiment confirmed our calculations. Yes, the aircraft by its equipping and configuration was fully capable of employment, particularly at night, as an effective long-range bomber. The results of the flight were written up in a summary that presented the basic parameters of the aircraft and its characteristics and showed all the calculations and data that were collected during the test flight. Colonel Titov, based on our suggestions, made a wise decision: that I, as his deputy, would go to the ADD headquarters and attempt “to make the case”. It was obvious that the division commander himself did not have the right to do this without permission of the corps commander. And we knew that General Sudets would never give this permission.

Executing this mission, I arrived at the office of the chief engineer of ADD, Lieutenant General of Engineering-Technical Services I. V. Markov, and reported that my visit was unofficial and I was asked to deliver a report about our long-range flight. We believed that having done so would further enable us to suggest ourselves, the 222d BAD, as a candidate for assignment to ADD.

I.V.Markov smiled understandingly, and said that the essence, and not the appropriateness, of our actions was paramount. “Give us your summary report, we already also know something about your division.” He studied the report closely and asked several questions regarding the qualitative and quantitative indicators of the division. He suggested that we leave the material with him for the commander in chief of ADD, General A. E. Golovanov. Several days later the commander, division navigator, and senior engineer were invited to General Golovanov’s office, where we reported in detail about the basis of the data, how we obtained it, and what remained unobtainable. After this we received an instruction from the GKO (State Defense Committee) that literally said, “222d BAD (division commander Titov, V. F.) is transferred to the forces of Long-Range Aviation”. The entire personnel component of the regiments and division command element received this pronouncement with great satisfaction. Thus, having spent less than three months assigned to the 1st BAK, as of 29 September 1942 we became the 222d BAD of ADD.

Materials preserved and made available for publication in Mir Aviatsii by E. E. Kulman

[1] These events occurred in the summer of 1942 [editor’s note]. 101 B-25s were delivered to the USSR through the Persian corridor in 1942 and 23 in 1943. [JG]

[2] 222d Bomber Aviation Division (BAD) [editor’s note].

[3] It is clear from this and other similar accounts that Soviet designers and engineers studied every piece of military and non-military equipment they received through lend-lease as part of a rational and purposeful technical intelligence collection operation. [JG]

[4] In the wartime Soviet Union, every category of person was assigned to a rations caloric norm, with front-line military personnel being at the top of this food chain and nonworking civilians at the bottom. Clearly, aviators enjoyed a ration norm of much higher caloric content than the workers from the TsAGI. [JG]

[5] A large number of aircraft production facilities located in the western portion of the Soviet Union had been evacuated to Soviet territory east of the Ural Mountains during the first year of the war. [JG]

[6] 4th Guards Gomel Air Corps, created on the basis of 4th Guards Long-Range Air Division [editor’s note].

[7] The pilots used the hydraulic brakes on the Mitchell just like the pneumatic brakes on their Soviet aircraft. This resulted in rapid failure of the friction linings of the pads [editor’s note].

[8] 37th, 16th, and 125th BAPs [editor’s note].

[9] V.A.Sudets (b. 1904) joined the Soviet Army in 1925 and completed pilot training in 1929. He served as an advisor and flight instructor in Mongolia during the mid-1930s and fought in the Soviet—Finnish War of 1939—40. From August 1941 he commanded the air forces of the 51st Army, then of the Volga Military District, and 1st Bomber Aviation Corps. From March 1943 until the end of the war he was commander of 17th Air Army. He received the award Hero of the Soviet Union in April 1945. After the war Colonel General Sudets was chief of staff and deputy commander in chief of the Soviet Air Force. He was promoted to Marshal of Aviation in 1955 and served as commander of PVO Strany [national air defense] forces from 1962—66. In 1966 he joined the group of general inspectors of the Ministry of Defense of the USSR. Marshal Sudets died in 6 May 1981 in Moscow. [Geroi Sovetskogo Soiuza, Moscow: Voyenizdat, 1988, II:538—9. JG]

[10] For additional reading on the subject of delivery of lend-lease aircraft through the Persian Corridor, go to T. H. Vail Motter, The Persian Corridor and Aid to Russia, chapter VII (Washington: Government Printing Office, 1952). According to this chapter, the first B-25s arrived at Basra on 12 March 1942. This volume is one of the Army “Green-book” series, the official history of the US Army’s participation in World War II. [JG]

[11] Mazuruk (b. 1906) was a civilian pilot from 1930—38, who received the HSU award for landing the first Soviet scientific expedition at the North Pole in 1937. He flew as a military pilot in the Soviet—Finnish War of 1939—40, and was commander of a Northern Fleet naval air force unit until 1943. He was then assigned as a division commander to the position of chief of the Alaska—Krasnoyarsk (ALSIB) ferry route. He retired at the rank of major general in 1953, but continued to fly arctic scientific missions. In 1956 he commanded a detachment in the first Soviet naval expedition to the Antarctic. [Geroi Sovetskogo Soiuza, Moscow: Voyenizdat, 1988, II:11—12. JG]

[12] The author, having flown on one of the B-25s from the USA, had a conversation with Mazuruk “at a heated level”, after which these disappearances ceased to occur [editor’s note].

[13] It was common practice in the Soviet Air Force to employ an air regiment until its combat strength in aircraft and crews was almost gone, then send it to a rear-area reserve base where the regiment was replenished in both crews and aircraft. In many cases this opportunity would also be used to transition the unit to a new type of aircraft. [JG]

[14] This was a slide-rule-type device common to all USAAF aircraft, known as a “computer, air navigation, dead-reckoning. [JG]

[15] The Il-4, also known as the DB-3F, was a twin-engine bomber with a payload of approximately 5,500 pounds, ceiling of 31,800 feet, cruise speed of 200 knots, and range of 2,400 miles. It had a crew of 3. [JG]

translation © James F. Gebhardt